Isn’t it just so stressful when you can’t find something at the time you REALLY need it? Whether you’re at work or home, your stuff is just all over the place! There’s just too much clutter!

Like, imagine you’re in a hurry to an important meeting but can’t find your documents. So, you had to frantically go through all your papers and drawers and basically had to flip your entire house. But in the end, you still end up late to your meeting and got an earful from your higher-ups. To make matters worse, you still have a disaster zone to clean up once you’re back home… Talk about a total nightmare!

Wouldn’t it be awesome if all your stuff was always where it’s supposed to be, easy to find, and ready to grab whenever you need it?

Well, what if I teach you a simple but powerful method that can help you do a complete overhaul of your place and have everything neat, organized, and most importantly, right ‘THERE’ just when you need it?

Well, get ready to Transform Chaos into Order with 5S Magic! Let’s get started!

WHAT IS 5S?

“5S” is a systematic method/framework for workplace management used to boost productivity, streamline operations, enhance cleanliness, and improve discipline, safety, and workplace organization [1, 2, 3, 4, 5, 17]. This method encourages workers to improve their working conditions and helps them learn to reduce waste, unplanned downtime, and in-process inventory [1, 4, 5, 17]. It also focuses on putting everything where it belongs and keeping the workplace clean, which makes it easier for people to do their jobs without wasting time or risking injury [2, 3, 18, 19].

Not only does the 5S method help create a well-maintained, standardized working environment, but it also ensures workers’ safety and comfort. The successful implementation of 5S enables effective problem-solving by addressing issues involving unnecessary materials, poor space management, disorganized work environment, and waste of time searching for materials and documents [1, 6, 7].

The term ‘5S’ originates from five Japanese words, each beginning with the letter ‘S’: Seiri, Seiton, Seiso, Seiketsu, and Shitsuke. These translate to Sort, Set in Order, Shine, Standardize, and Sustain, respectively [1, 2, 4, 8]. Each of these words is a step that serves a purpose, as their name entails, and must be applied to achieve its objective as a workplace management method. For instance:

SORT (Seiri)

The first S, ‘Sort’, involves identifying and sorting tools, products, documents, or any other item within a work area into ‘necessary items’ and ‘unnecessary items’. Necessary items would need to be grouped and categorized later, while unnecessary items would need to be removed and eliminated [1, 2, 9]. Unnecessary items would include damaged, expired, impractical, or unused items [1].

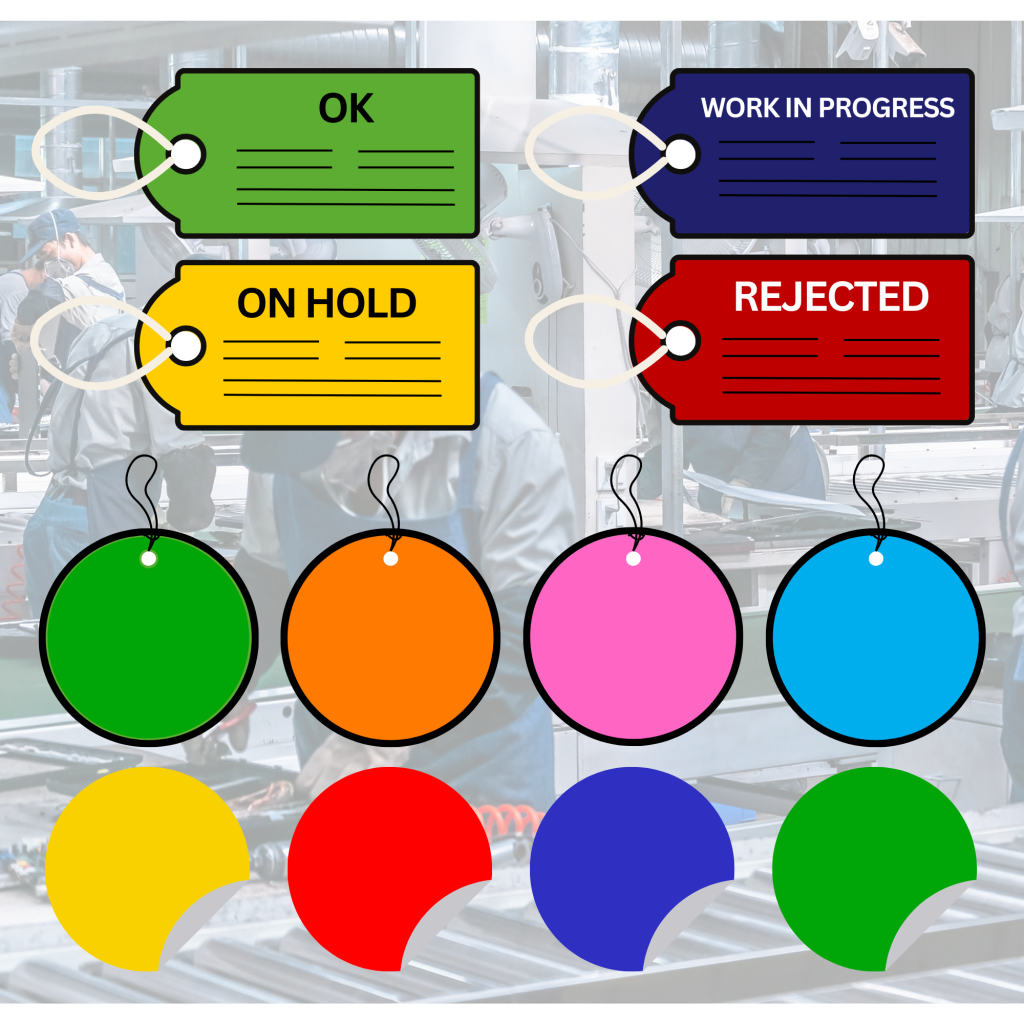

Removing unnecessary items is essential for clearing up clutter and freeing up space, allowing for safer and better organization of one’s work area [1, 3, 4]. The removal can be done through tagging (a.k.a 5S Red-Tagging), which helps quickly and visually indicate the unnecessary items and allows communication between employees about the information of specific items [1]. Those with red tags will be gathered in a designated area and reviewed until a decision is made – whether they are to be disposed of, relocated, or repurposed [1, 17].

SET IN ORDER (Seiton)

Once items are sorted accordingly and waste is removed, the second S, ‘Set in Order,’ can be implemented. Set in Order focuses on organizing necessary items efficiently. These items should be properly stored in designated locations based on factors such as the similarity of items, frequency of use, workplace layout, safety considerations, and ergonomic efficiency [1, 2, 6]. Those that are frequently used should be stored close to where the work is done and be arranged systematically if the work follows a pattern/order for smoother and more efficient workflow.

Moreover, proper placement of items is important to reduce unnecessary and repetitive motions, minimize mess, quicken the time to find and return items, and enhance workplace safety, which ultimately improves productivity and work performance [1, 2, 3, 10].

Additionally, visual cues placed around the work area can enhance the visibility of stored and organized items. For example, storage spaces and compartments should have clear labels, signage, and markings to serve as visual aids, making it easier to identify items and their designated locations [17]. Clear identification is especially crucial for hazardous materials or equipment that pose safety risks. Proper labeling ensures that individuals remain aware of potential dangers and avoid entering restricted areas without the necessary protective gear.

Remember that there is “a place for everything and everything in its place”. Working in an environment with a good organization and layout not only allows a less stressful working experience but will also help boost workers’ motivation and productivity.

SHINE (Seiso)

Now that the work area is well sorted out and set in order, ‘Shine’, the third S, is well to be carried out. Shine aims at maintaining a clean and well-maintained work area by eliminating any type of impurities, dirt, dust, inefficiencies, and foreign contaminants [1, 4, 10]. Shine is a continuous process – going beyond cleanliness – that ensures workspaces, tools, and equipment are always kept in immaculate condition through regular cleaning and inspections [1].

A clean and well-maintained environment not only improves efficiency and productivity but also promotes safety by reducing the risk of accidents and equipment malfunctions. For instance, neglecting regular cleaning of the air conditioner can lead to mold, allergens, and dust build-up which can result in poor air quality and potential health issues for workers. In this case, cleanliness contributes to healthier work areas, protecting both the people and materials from potential damage or contamination [2, 3].

On top of that, workers will feel more comfortable and take greater ownership of their environment, fostering discipline, professionalism, and alignment with their work goals [9]. By integrating Shine into daily routines, organizations create a more efficient, safe, and visually appealing workspace, ultimately enhancing overall work performance [4, 10].

STANDARDIZE (Seiketsu)

With all the first three 5S steps being done and dusted, it is imperative to have a standardized routine to maintain all changes made during the previous stages. This is where the fourth S, ‘Standardize’, comes in. Standardize helps in maintaining order by ensuring that improvements done during all three preceding stages are sustained through clear standards and procedures [1, 3, 4]. This involves documenting work methods, creating standardized procedures, providing training, and ensuring that employees understand their roles and responsibilities in upholding 5S practices [1, 4, 10].

Organizations usually set high standards in their procedures to maintain the quality of their products and services, not only for internal consistency but also to build trust with stakeholders, ensure compliance with regulatory standards, and support successful audits [2]. Standardization ensures that best practices become ingrained in the company’s culture, replacing old habits with more efficient behaviours [9, 10]. To achieve this, companies use tools such as training manuals, work instructions, visual workplace systems, and one-point lessons to communicate expectations clearly [1, 3].

Additionally, reinforcing new standards through reminders like visual cues, task trackers, and emails can help employees internalize these practices over time [9]. By establishing structured processes, organizations can sustain the improvements made through 5S, leading to greater efficiency, consistency, and long-term success.

SUSTAIN (Shitsuke)

After all four stages have been applied, the most important stage must be done; 5S’s ‘Sustain’. Sustain focuses on developing self-discipline and ensuring that 5S practices become ingrained in the organization’s culture [1, 2, 3, 9]. It requires employees to consistently observe and follow established rules while promptly addressing any deviations from the 5S principles [1, 2]. However, while it is the most important stage, it is also the most difficult one to execute.

For long-term success, organizations must continuously maintain established procedures, conduct regular audits, and reinforce 5S as a daily habit [3, 4]. This step prevents frequent changes in work methods, ensuring stability and efficiency in operations [2].

A strong culture of sustainment relies on both employee commitment and management support, with leadership playing a crucial role in motivating and guiding staff [1]. There is no point in putting in all those efforts to apply 5S if things just go back to old habits. By implementing structured systems such as routine observation of standard work practices, training programs, and regular communication, organizations can foster discipline, improve adherence to 5S standards, and drive continuous improvement [9, 10, 11]. In brief, sustaining 5S leads to a more organized, efficient, and high-performing workplace.

5S is an important tool to boost morale and instill motivation among workers [5]. Most companies now apply 5S as a workplace management tool for more optimized inventories, organized work environments, and streamlined processes to maintain operational cleanliness standards by eliminating non-value-added activities and clutter [5, 11].

Implementing 5S enables organizations to create a safe, productive, healthy, and well-organized work environment while ensuring compliance with standards that drive quality improvement. This will also foster a strong management culture and a workforce that upholds best practices [5].

While 5S was mostly implemented in the workplace, it can also be applied during your leisure time. 5S is a way of life, serving as a guide to how you conduct yourself every day and wherever you are. If taught at an early age, it can become a natural way of living, helping individuals develop discipline, organization, and efficiency in all aspects of life. This mindset fosters a culture of continuous improvement, ensuring that good habits become second nature and contribute to a more productive and harmonious environment, both personally and professionally.

SAFETY (THE 6S TOOL)

On top of the main five pillars in 5S, there is also one special pillar that organizations can add when they need to heighten their health, security, or safety measures; a.k.a “Safety”. Safety focuses on eliminating risks in work processes through strategic organization of the workspace to prevent hazards [18, 20]. This includes designing more ergonomic workstations, implementing clear markings at intersections for workplaces with vehicles (i.e., trucks and forklifts), identifying hazardous areas to prevent accidents and injuries, and improving signage and labeling for dangerous materials and tools to enhance safety and awareness [18]. While some think that Safety can already be established within the 5S itself, some also believe that this new S can still be implemented for organizations leaning more into safety and security in their 5S initiative [18].

A study by Soltaninejad et al. [12] focused on developing and validating a framework that integrates essential safety practices – i.e., visualization, Job Safety Analysis (JSA), and the Plan-Do-Check-Act (PDCA) approach – into the 5S methodology. This implementation of grounded theory led to the development of the theoretical framework that enhances the understanding of the 6S system. The study highlights how safety tools, training, and reflexivity contribute to achieving a safer and more efficient workplace. Practical applications of 6S in real projects demonstrated improvements in workplace safety, productivity, and project quality. The study believes that adopting 6S fosters a stronger safety culture and provides valuable guidance for both employees and managers.

Based on the results from interview analysis and 6S application in real projects, it was found that 1) complimentary safety practices (visualization, JSA, and PDCA) are critical for safety in construction projects, complementing the 5S methodology; 2) three key features, training (education), reflexivity (reasoning), and complementary safety tools, are essential to enhance the 6S system’s effectiveness; 3) grounded theory evidence suggests that incorporating the complementary safety practices significantly reduces safety accidents, outperforming the original 5S methodology; 4) implementing 6S increased worker safety climate, reduced cycle times, and improved floor area utilization, all contributing to better project quality and productivity; 5) the proposed 6S framework could enhance safety rates at job sites. It helps foster a safety culture, supported by questionnaire results showing positive outcomes; and 6) the study’s findings offer practical tools and frameworks to support teams in construction and manufacturing, improving safety and operational efficiency. Ultimately, the study has provided a good demonstration of how 5S can be expanded for more enhanced safety measures. The results are expected to provide valuable guidelines for employees and project managers to foster a safer work environment.

BRIEF HISTORY OF 5S

As many people know, 5S is a workspace management method that emerged in Japan as a consequence of the application of the “Kaizen” culture (continuous improvement in the personal, family, social, and professional life) [13]. Kaizen means “Change for the better” [14]. 5S gained recognition after its implementation within Toyota’s manufacturing system, Toyota Production System (TPS), as a quality management approach in Japan [4, 18, 21]. Two major frameworks for applying 5S in business environments were introduced, namely by Takashi Osada in his book “The 5S’s: Five Keys to a Total Quality Environment” (1991) and Hiroyuki Hirano in his book”5 Pillars of the Visual Workplace: The Sourcebook for 5S Implementation” (1995) [4]. Hirano’s framework provided a structured approach to improvement, outlining a series of identifiable steps, each building upon the previous one [7].

5S is one of the many tools of Lean Production, which was designed to reduce operational lead time through the elimination of non-value-adding activities [5, 14, 22]. 5S is recognized as a key industrial technique that helps organizations stand out by fostering efficiency and organization [5]. Over time, it has now become one of the most widely used Lean Production tools, finding applications across various industries, including manufacturing, automotive, and healthcare [15, 18, 22].

BENEFITS OF 5S

5S offers a wide range of benefits, not only in the workplace but also in our personal lives and households. While we’ve already highlighted some of these advantages, here are a few more that demonstrate how impactful these five simple steps can truly be:

Optimizes and streamlines workflow

Implementing 5S enhances both effectiveness and efficiency in organizational processes [3]. It helps streamline the flow of materials and products between departments, reducing inefficiencies and improving coordination [8]. By fostering an orderly workflow that transcends departmental boundaries, 5S creates a more seamless and productive work environment [8].

Enhances workplace organization and standardization

5S promotes better workplace organization by ensuring that tools and materials are properly managed, preventing the loss of essential items [4]. It helps eliminate non-value-adding time, leading to increased productivity and improved quality [10]. Through effective workplace management, employees can operate in a more structured and efficient environment [7]. Additionally, 5S emphasizes ongoing inspection and maintenance of equipment, reinforced by documented standards, which helps reduce downtime and enhance output quality [20].

Boosts productivity

5S significantly increases productivity by eliminating time wasted searching for tools and materials, ensuring that only essential items are kept in the workspace [1]. It helps establish and maintain a productive and high-quality work environment [3], ultimately leading to greater efficiency and output [4, 23, 24]. Additionally, standardizing work processes reduces variations and mistakes, minimizing faults and failures, which results in improved consistency, quality, and overall productivity [19].

Saves Costs and Optimizes Storage Space

The 5S methodology helps reduce costs and maximize storage efficiency by ensuring better utilization of materials and workspace [1]. Proper organization minimizes wasted space, allowing for more effective use of work areas [4]. By eliminating unnecessary stockpiles and consolidating tool storage, businesses can free up valuable space for more productive applications, ultimately improving profitability [19]. This streamlined approach leads to cost savings and more efficient resource allocation [23].

Eliminate non-value-added activities and waste

5S helps identify and eliminate waste in various forms, such as excess storage, wasted labour time, and lengthy production or setup processes [3]. By reducing repetitive mistakes through error-proofing, it enhances overall efficiency [4]. The method also minimizes unnecessary time, space, and human resource wastage, ensuring smoother operations [8]. Workers spend less time searching for tools, equipment, and materials, as well as preventing unnecessary movement of materials and resources within the industry [7]. By removing clutter and organizing essential items, 5S enhances time management, reduces non-value-added activities, and significantly cuts down waste [19, 23, 24].

Maintains and improves work equipment/machinery condition

5S leads to the improvement of machine conditions through regular cleaning and maintenance [1]. It fosters better maintenance practices and safety [3], while also enhancing equipment reliability [3]. By keeping tools and equipment clean, regularly inspecting them, and using them in a standardized way, downtime is reduced. Preventive maintenance becomes more effective, and major failures can often be avoided altogether [19].

Enhances product and service quality

Implementing 5S leads to the improvement of product and service quality by fostering a well-organized, efficient, and clean work environment. A structured workspace reduces errors, ensures consistency, and enhances overall performance, resulting in higher-quality outputs for customers [1]. By maintaining an orderly system, businesses can sustain improved quality in both their products and services, ultimately boosting customer satisfaction and reliability [3]. This continuous focus on organization and efficiency contributes to overall operational excellence and quality improvement [23].

Improve workplace cleanliness and safety

The 5S methodology significantly improves workplace cleanliness and safety by promoting an organized and well-maintained environment. A cleaner workspace leads to better working conditions [3, 4, 8] and reduces safety incidents [1]. Improved maintenance practices enhance overall safety and accident prevention while eliminating hazards (like clutter and spills) and minimizing trip risks and fatigue – reducing injury rates [3, 19]. By fostering a culture of routine cleaning and organization, 5S not only enhances safety but also boosts employee morale [23, 24], creating a healthier and more productive work environment [4].

Improve workforce motivation, discipline, and teamwork

The 5S methodology enhances workforce motivation, discipline, and teamwork by fostering a structured and collaborative work environment. It instills a greater sense of responsibility and teamwork among employees while also promoting discipline across various departments [3, 4]. Effective implementation leads to higher employee morale as workers feel valued and recognized for their contributions [4, 7, 19]. Plus, improved communication reduces organizational gaps, strengthening collaboration [4, 7]. By creating an environment where employees take pride in their work and contribute to company growth, 5S drives motivation, engagement, and overall team effectiveness [19].

Fosters Kaizen culture (continuous improvement)

The 5S methodology cultivates a Kaizen-driven workplace by embedding discipline, engagement, and proactive problem-solving. It fosters a culture of continuous improvement, encouraging employees to enhance work processes and address inefficiencies [1, 3]. Increased discipline and engagement create a structured, accountable environment, whereas strong human relationships promote collaboration [3, 4]. By giving employees ownership over their workspaces, 5S strengthens accountability and personal investment, laying a foundation for ongoing improvement [O5, O8]. Operators optimize their areas for efficiency through Sort and Set In Order, while Shine instills pride in maintaining cleanliness [20]. Standardize and Sustain reinforce discipline, stability, and quality output, embedding a lasting culture of productivity and continuous growth [20].

A Versatile and Universal Tool

While the 5S methodology is mostly associated with production and manufacturing industries, it is a universally applicable tool that can be implemented across various industries and settings, from healthcare, customer service, and machine shops to administrative departments and corporate offices [8, 24]. Its flexibility allows organizations to eliminate waste and enhance efficiency, organization, and productivity in any work environment, regardless of industry or function.

SIMPLE WAY TO APPLY 5S

The best part of 5S is that it is so versatile that anyone can apply 5S. Whether you’re a child, adult, student, doctor, housewife, office worker, or just anyone – as long as you learn how to properly apply it in your work and daily life, 5S can work for you.

Plus, even though 5S uses five simple steps, the concept is so flexible that it can be formulated in a way that can suit any type of work area, for both work and home activities.

You might have even done it throughout your life without even knowing it as the 5S method.

As explained previously, 5S encompasses five stages: Sort, Set In Order, Shine, Standardize, and Sustain. I have already explained each of their functions and brief ways to carry them out. Here is a simpler, straight-to-the-point way to apply 5S – to give you the gist of it. Once you already know the basics, you might even get an idea to expand and construct it into a framework that works best to help your type of work.

So, let’s get to it!

SCENARIO: Imagine yourself living in a messy apartment where most sections of the house (i.e., kitchen, bedroom, laundry room, closet, dining area, study room, bathroom) look like they’re merging haphazardly. You decide to do a deep clean of the entire apartment. It seems like a tough job, but do not fret! You have 5S as your mighty weapon!

Sort

Sort involves sorting out items from necessary and unnecessary and throwing out those that are unnecessary. But before you decide which is which, ask yourself these questions for each item [O9];

- What is the purpose of this item?

- Does this item belong here?

- Who uses this item?

- How frequently is this item used?

So, for the scenario here, the apartment has several different sections, so you need to go to each area at a time.

You should already know what items you usually keep in each section, right? So, ask yourself the aforementioned questions and sort your items out. Sort those that belong in each area, those that don’t (should be in another section of the apartment), and those that need to be removed from your apartment.

Items that are clearly waste, such as rubbish, broken items, or empty, non-reusable containers, should be disposed of immediately. But if you have too many items and can’t decide whether to keep, donate, sell, or discard them, use the ‘red-tagging’ method. Attach tags to uncertain items and set them aside for later review. Regularly assess these tagged items, and if they remain unused after some time, remove them from the area – either by discarding, donating, selling, or placing them in storage.

Set In Oder

Set In Order focuses on setting the necessary items in order within the work area by organizing and arranging them to ensure efficiency and convenience. They should be categorized and placed based on;

- Type of items: Gather and group items that have similar functions/characteristics (e.g., grouping hair products or utensils together like comb, hair serum, and hair dryer or grouping all supplements and medicines in one box only)

- Frequency of use: Daily-use items (e.g., keys, phones, chargers, skin care products, etc.) should be easily accessible

- Storage: Store items in shelves, storage bins, drawers, organizers, etc, to avoid clutter and stick labels on them for easier identification

- Layout and flow of the work area: Ensure pathways are clear and that frequently used areas (kitchen and study desk) are organized in a way that minimizes movement and confusion.

- Safety considerations: Avoid stacking heavy items too high, ensure wires are neatly arranged, and eliminate trip hazards.

For instance, keep your daily essentials like clothes, electronics, accessories, and hygiene products within easy reach. If you have clothes you only wear during special occasions, you should hang or place them behind or below your everyday clothes. This will help you access your daily clothes faster and not have the special clothes get in the way and risk making a mess. Or, if you rarely have guests over, you can store your extra sleeping necessities or your fancy China in storage bins/shelves. You can even label the storage bins/shelves for easier identification in the future.

Shine

Shine aims to keep the area tidy and spotless through regular cleaning and maintenance to prevent mold, dirt, and dust buildup whilst improving hygiene, maintaining tools and equipment, and preventing damage.

To use Shine in your bedroom, you should do daily cleaning (e.g., take out the rubbish, make your bed, wash dishes, sweep the floor, wipe the dining table, etc.), and weekly cleaning (e.g., do laundry, wash bedsheets, clean windows, wipe dust from surface areas, etc.), deep cleaning (e.g., clean refrigerator, scrub and disinfect the bathroom, de-greasing kitchen hoods, clean the insides of ovens, microwaves, fridges, and freezers, etc.), and regular maintenance checks (e.g., check for leaks, broken items or those require repairs, etc.).

Standardize

Standardizing is about creating a system by establishing habits and routines to maintain the cleanliness and organization done in the previous steps. This ensures consistency and prevents reverting to your old, messy habits.

Now that your apartment has been organized and cleaned, you need to set a cleaning routine. You can create cleaning schedules based on how many times specific areas or items require cleaning and organization (e.g., daily, once every two weeks, monthly, etc.), as demonstrated in Shine. If you ever decide to have a roommate, you can even create a visualized schedule for them and assign tasks and take turns to complete them, as well as teach them where and how items should be kept.

Sustain

Sustain is about maintaining and continuously improving the 5S system. Now that you have already applied the 1st-4th S, you need to be disciplined and committed to this new system in your home so that you won’t go back to your old habits and waste all that effort.

Therefore, to successfully conduct Sustain, you need to regularly check if your items and organization system are in order, remind yourself and anyone visiting/staying in your home to follow your system, make this new daily routine second nature to you, and look for other areas for improvement within the system for better efficiency.

For example, after successfully keeping your study area clutter-free for a month, you might decide to add a small whiteboard to list daily tasks or invest in drawer organizers to further improve efficiency.

MULTIPLE WAYS TO APPLY 5S

EXAMPLES OF 5S AT WORK

Laptop work files/folders:

- Sort: Delete unnecessary or duplicated files and remove outdated documents (or put them in an archive folder).

- Set in Order: Organize files into clearly labeled folders (e.g., “Projects,” “Reports,” “Invoices”) with the year and/or month for easier and faster access.

- Shine: Regularly clean the desktop, remove unused shortcuts, and clear temporary files.

- Standardize: Use consistent naming conventions (e.g., “YYYY-MM-DD_ProjectName”) and file storage protocols.

- Sustain: Schedule a monthly cleanup to keep files well-organized and prevent clutter.

Toolbox:

- Sort: Remove broken or unused tools.

- Set in Order: Arrange tools by type and frequency of use; use shadow boards or labeled compartments.

- Shine: Clean tools regularly to prevent rust and wear.

- Standardize: Ensure every tool has a designated place and establish a system for returning tools after use.

- Sustain: Conduct routine checks to maintain organization and replenish missing tools.

Office department:

- Sort: Remove unnecessary documents, outdated files, and unused office supplies. Place them in proper storage if required for record purposes.

- Set in Order: Assign dedicated spaces for commonly used items (e.g., printers, stationery, meeting materials). Label compartments/drawers/cabinets clearly to ensure easy identification and quick access.

- Shine: Keep desks, shared spaces, and common equipment clean and well-maintained.

- Standardize: Implement clear guidelines for desk organization, file storage, and shared equipment use.

- Sustain: Promote a culture of tidiness through regular check-ins, team accountability, and periodic decluttering.

EXAMPLES OF 5S AT HOME

Kitchen:

- Sort: Discard expired food, unused utensils, and broken appliances.

- Set in Order: Store frequently used items (e.g., spices, pots, and pans) within easy reach and label pantry shelves, spices containers, etc.

- Shine: Wipe countertops, clean spills immediately, and regularly deep-clean appliances.

- Standardize: Assign specific storage areas for items (e.g., dry goods in labeled containers, knives in a designated drawer).

- Sustain: Create a habit of cleaning as you go and do a weekly fridge/pantry check to remove clutter.

Wardrobe:

- Sort: Donate or discard clothes that no longer fit or are rarely worn.

- Set in Order: Arrange clothes by category (e.g., workwear, casual, special occasions) and use storage bins for accessories.

- Shine: Keep shelves and drawers clean and regularly dust and vacuum the wardrobe area.

- Standardize: Use uniform hangers, folding techniques, and drawer dividers to maintain order.

- Sustain: Follow a “one-in, one-out” rule – whenever you buy a new item, remove an old one.

Children’s playroom:

- Sort: Remove broken toys, outgrown items, and games with missing pieces.

- Set in Order: Store toys in labeled bins, use shelves for books, and create designated play zones.

- Shine: Encourage the children to clean up after playtime and wipe surfaces regularly.

- Standardize: Implement a toy rotation system to keep things fresh and prevent clutter.

- Sustain: Establish a cleanup routine and involve the children in maintaining the space.

VISUAL TOOLS FOR 5S

Floor marking tape

Labels and signs

Shadow board and Toolbox foam

Coloured Tags

CASE STUDIES ON 5S IMPLEMENTATION

5S is a very popular method that has proven its effectiveness beyond the automobile and manufacturing industries since its introduction at Toyota. Due to its versatility, many organizations – healthcare, education institutions, manufacturing, government, etc. – have employed 5S in their workplace – from work items organization, cost control of inventories, and warehouse mapping to efficient customer response and increased process quality [5, 18].

Hisahiro Ishijima [16] conducted a study on the relationship between the implementation of 5S and patient waiting time in different service points (medical records, consultation room, laboratory, and pharmacy) in outpatient departments (OPDs) of 16 hospitals in Tanzania. The hospitals were divided into treatment and control groups. Before the intervention, a baseline study was conducted for each hospital. Then, after one year of 5S implementation, an end-line study was carried out to compare the average patient waiting time for both groups before a Difference-In-Difference (DID) analysis was conducted in the treatment group. It is to assess the effect of implementing the 5S method on the reduction of patient waiting time without bias from baseline imbalance. The results from the treatment and control groups show that the implementation of 5S creates a significant positive impact on the reduction of patient waiting time in the OPD service points – especially sections that perform repetitive tasks. While the laboratory and pharmacy sections showed only a slight reduction in time after the 5S intervention, a significant improvement was evident in the medical records and consultation rooms, highlighting the effectiveness of the 5S implementation.

Makwana and Patange’s [4] study investigates the implementation of 5S at a plastic machinery manufacturing company in India and the relationship between 5S and productivity. It aims to use 5S to improve productivity by reducing the assembly and search time of materials and creating an organized storage area. The study carried out a five-phase activity comprising of 1) company baseline evaluation; 2) 5S awareness training; 3) implementation of 5S steps in the store department and assembly area in addition to weekly 5S auditing; 4) SOP documentation preparation; and 5) 5S audit and sustenance mechanism development, reward programme development, and 5S and productivity level hypothesis testing. Results showed that the 5S method has greatly improved the work culture and employee morale within the company. Additionally, a significant reduction in the search time for materials was achieved, from 8.6 hours to only 3.1 hours. Subsequently, this reduction of search time has helped improve the assembly time. On top of that, 5S has helped improve the assembly line and optimize the utilization of resources. Moreover, 5S has shown a positive relationship to the productivity level. It has increased from 75% to 101% while 5S score increased from 20% to 80%. This has ultimately shown the effectiveness of 5S implementation in an organization.

Sharma and Lata [8] conducted a study on the implementation of 5S to eliminate waste and improve efficiency, environmental performance, housekeeping, health, and safety in a copper wire drawing company in India. Results discovered that the 5S method has helped;

- improve cleanliness and work environment (leading to improved employee morale and efficiency)

- minimize search time and boost productivity by providing employees with their own personalized workstations and supplies

- enhance machinery performance and lifespan through regular machine cleaning

- save time, reduce frustration, and improve workflow through organizing documents

- prevent order mix-ups and improve inter-department coordination by better store organization

Rizkya et al. [6] studied the application of 5S in a welding workshop and highlighted the contribution of 5S implementation to organizational progress in terms of quality, productivity, work safety, and worker moral values. Through observation, interviews, documentary analysis, and quantitative evaluation, the results have shown positive outcomes in the 5S implementation. For instance, through 5S, goods were grouped by size, characteristics, and similarity, leading to space usage optimization to 30.98 m² – reducing space utilization by 11.20%. Not to mention, the search time for equipment and goods was reduced by 18.75%. This includes search time for documents, tools, and stationery whilst minimizing unnecessary movements and excessive space; thus, bringing about improved efficiency in overall operations in the welding workshop.

To sum it up, by learning and instilling a simple and straightforward method such as 5S in your everyday life, you can transform chaos into order! You don’t have to struggle with overwhelming clutter, disorganization, and inefficiencies anymore. Embracing the 5S method can revamp not only your work environment but also your home – bringing more order to your life and making daily activities smoother and more manageable. Whether it’s organizing work files or kitchen essentials, streamlining workflows or household chores, or maintaining clutter-free workstations or living spaces, 5S fosters a structured, efficient, and stress-free environment. With 5S, you’ll enhance workflow, reduce waste, and establish sustainable habits that boost both productivity and peace of mind – at work and at home.

NEED TRAINING?

Then, come and enroll in our Lean Six Sigma training now to master methodologies and techniques that drive profitability through waste elimination, quality management, and continuous improvement!

We offer flexible training modes: public training, in-house training, and online training – choose the one that best suits your needs

If you’re for hands-on Lean Six Sigma consultation, then we have your back! We also provide expert guidance in Root Cause Analysis and Value Stream Mapping training, Capability Development Programmes (CDP), and Lean & Quality Management projects – covering project selection, coaching, tollgate reviews, and audits to ensure successful implementation and measurable results.

Take the next step towards operational excellence – contact us today!

REFERENCES

[1] P. Kabiesz and J. Bartnicka, “5s system as a manner for improving working conditions and safety of work in a production company,” Multidisciplinary Aspects of Production Engineering – MAPE, vol. 2, no. 1, pp. 496–507, Sep. 2019. doi:10.2478/mape-2019-0050

[2] S. Gupta and P. Chandna, “A case study concerning the 5s lean technique in a scientific equipment manufacturing company,” Grey Systems: Theory and Application, vol. 10, no. 3, pp. 339–357, Apr. 2020. doi:10.1108/gs-01-2020-0004

[3] C. Veres (Harea), L. Marian, S. Moica, and K. Al-Akel, “Case study concerning 5s method impact in an automotive company,” Procedia Manufacturing, vol. 22, pp. 900–905, 2018. doi:10.1016/j.promfg.2018.03.127

[4] A. D. Makwana and G. S. Patange, “Strategic implementation of 5S and its effect on productivity of Plastic Machinery Manufacturing Company,” Australian Journal of Mechanical Engineering, vol. 20, no. 1, pp. 111–120, Oct. 2019. doi:10.1080/14484846.2019.1676112

[5] Md. M. Shahriar, M. S. Parvez, M. A. Islam, and S. Talapatra, “Implementation of 5s in a plastic bag manufacturing industry: A case study,” Cleaner Engineering and Technology, vol. 8, p. 100488, Jun. 2022. doi:10.1016/j.clet.2022.100488

[6] I. Rizkya, K. Syahputri, R. M. Sari, and I. Siregar, “5s implementation in Welding workshop – a lean tool in waste minimization,” IOP Conference Series: Materials Science and Engineering, vol. 505, no. 1, May 2019. doi:10.1088/1757-899x/505/1/012018

[7] A. A. Ahire, A. B. Chaudhari, O. S. Ahirrao, and V. B. Sarode, “Increasing productivity through implementation of 5S methodology in a manufacturing industry a case study,” International Journal of Scientific Research in Multidisciplinary Studies, vol. 7, no. 7, pp. 51–57, Jul. 2021. doi:10.26438/ijsrms/v7i7.5157

[8] K. M. Sharma and S. Lata, “Effectuation of Lean Tool ‘5s’ on materials and work space efficiency in a copper wire drawing micro-scale industry in India,” Materials Today: Proceedings, vol. 5, no. 2, pp. 4678–4683, 2018. doi:10.1016/j.matpr.2017.12.039

[9] P. B. Sangode, “Impact of 5s methodology on the efficiency of the workplace: study of manufacturing firms”, International Journal of Research in Commerce & Management, vol. 9, no. 12, 2018.

[10] O. Omogbai and K. Salonitis, “The implementation of 5S lean tool using system dynamics approach,” Procedia CIRP, vol. 60, pp. 380–385, 2017. doi:10.1016/j.procir.2017.01.057

[11] T. ‘Susie’ Leming-Lee, S. Polancich, and B. Pilon, “The application of the Toyota Production System Lean 5S methodology in the operating room setting,” Nursing Clinics of North America, vol. 54, no. 1, pp. 53–79, Mar. 2019. doi:10.1016/j.cnur.2018.10.008

[12] M. Soltaninejad, M. S. Fardhosseini, and Y. W. Kim, “Safety climate and productivity improvement of construction workplaces through the 6S system: Mixed-method analysis of 5S and Safety Integration,” International Journal of Occupational Safety and Ergonomics, vol. 28, no. 3, pp. 1811–1821, Jun. 2021. doi:10.1080/10803548.2021.1935624

[13] M. Jiménez, L. Romero, J. Fernández, M. del M. Espinosa, and M. Domínguez, “Extension of the LEAN 5S methodology to 6s with an additional layer to ensure occupational safety and Health Levels,” Sustainability, vol. 11, no. 14, p. 3827, Jul. 2019. doi:10.3390/su11143827

[14] W. Ulrych, “The 5s method and its influence on employee work requirement practices which can hamper lean service introduction,” Journal of Positive Management, vol. 10, no. 2, pp. 30–41, Oct. 2020. doi:10.12775/jpm.2019.005

[15] S. Pawlak, K. Nowacki, and H. Kania, “Analysis of the impact of the 5s tool and standardization on the duration of the production process – case study,” Production Engineering Archives, vol. 29, no. 4, pp. 421–427, Oct. 2023. doi:10.30657/pea.2023.29.47

[16] H. Ishijima, E. Eliakimu, and J. M. Mshana, “The ‘5s’ approach to improve a working environment can reduce waiting time,” The TQM Journal, vol. 28, no. 4, pp. 664–680, Jun. 2016. doi:10.1108/tqm-11-2014-0099

[17] “Lean Thinking and Methods – 5S,” EPA, https://www.epa.gov/sustainability/lean-thinking-and-methods-5s (accessed Feb. 24, 2025).

[18] “What is 5s?,” 5S Today, https://www.5stoday.com/what-is-5s/ (accessed Feb. 24, 2025).

[19] DuraLabel Staff, “The 5S System Explained: From Origins to Implementation,” DuraLabel, https://resources.duralabel.com/articles/what-is-5s (accessed Feb. 24, 2025).

[20] “5 key reasons why 5s is so essential to manufacturing,” Why is 5S Important in Manufacturing? | Lean Production, https://www.leanproduction.com/5s/5s-and-manufacturing/ (accessed Feb. 24, 2025).

[21] “Everything You Need to Know About 5S Methodology,” NEXGEN, https://www.nexgenam.com/blog/what-is-5s-methodology/ (accessed Feb. 24, 2025).

[22] “The Origin of the 5S Method: Sort, Set in Order, and So On,” Stop-Painting.com, https://blog.stop-painting.com/the-origin-of-the-5s-method-sort-set-in-order-and-so-on/ (accessed Feb. 24, 2025).

[23] L. Paulise, “5S methodology in Lean Thinking: Principles & Implementation,” Simplilearn.com, https://www.simplilearn.com/implementing-5s-methodology-to-achieve-workplace-efficiency-article (accessed Feb. 24, 2025).

[24] “Five S Tutorial,” 5s – what are the five S’s of lean? | ASQ, https://asq.org/quality-resources/five-s-tutorial (accessed Feb. 24, 2025).